|

The past week was very challenging around here. You probably heard of the "heat dome" that descended on BC and the Pacific Northwest - it was over 40°C around our house. I did go and work in Redford for two days but only did 30-45 minutes each day as I was covered in sweat after that time. I did decide how to run wires for the ceiling lights and managed to install the wiring for the front lights. Besides the heat wave it was just a busy time. Angela officially retired on June 30 :) :) :) Congrats to her after 30 years as a teacher. She did terrific and impactful work and the cards - especially the ones from students were wonderful. She's sad about the conditions this year and how it has affected her and the other retirees but she's also "ready" for the next phase in her life. The other "biggie" this week was that both of us got our second COVID vaccinations (me on Wednesday and her on Thursday.) We led off with AZ back in April and followed that with Moderna this week. We both got hit with lots of aches, pains, and tiredness a day after but fully recovered after the second day and are so happy that we're double vaccinated (also happy with a mix and match.) Extra careful for two more weeks and then just cautious with preventative measures when necessary. Yay!!

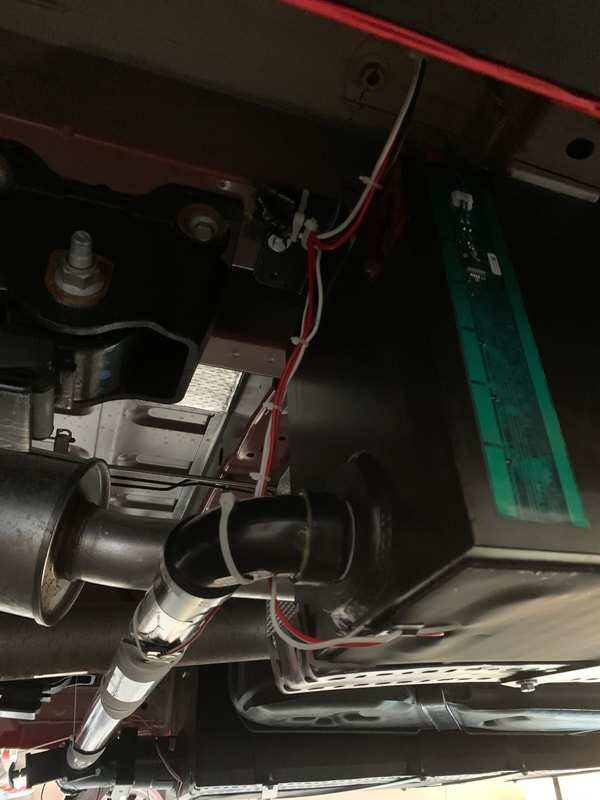

After installing the electrical system I was kind of thinking, "Hmmm, I hope there's no short circuit that starts an electrical fire..." I went online and ordered two fire extinguishers for Redford. There are many types of extinguishers and in particular I needed a class ABC type. Interestingly, the ones I bought are rated for BC (B: flammable liquids, solvents, oils, gas, etc. C: electrical, energized wires, appliances, etc.) but also handles common materials like paper and wood but isn't specifically rated for A. Given that we've got rather large (618 amp-hours) of lithium iron phosphate batteries I definitely wanted the "C". We needed something fairly compact as well. I found a nice tidy home for the extinguisher behind the passenger seat. I'm using velcro straps to secure the unit in place as the base of the seat has openings that I could thread the straps through. I may have to put in some felt pads if the extinguisher moves around too much when driving but I'm happy with the location; it is clearly visible, out of the way, but easily accessible. It's interesting how each time I have to cut or drill a hole in Redford there's a bit of a delay/lag in the work process. It's partially being careful but it also seems to coincide with other life events that get in the way as well. After the grey and black tank heating pads arrived last week, today I finally drilled the holes into the floor and installed one set of wires. There was a fair bit of thinking to do as I had to learn how the elbow and tank pads got wired, i.e., how was I going to connect to ground, what gauge wires, how to install the switch, and also how the SeeLevel II tank sensor system worked. In the end I decided against grounding (for both the heaters and the SeeLevel system) to some point on the exterior chassis and chose to run a ground wire back into the van electrical panel. A 10 awg wire to the switch and then 12 awg wires from the switch to the components was what I ended up with. But then I also had to figure out what switch to use. Always another domino waiting to fall in a series of decisions. The switch for 20 DC amps was a different style than other illuminated switches that I already bought so I decided to also change the water pump to the same style (round rocker switch). The install of the pads went well - the bottom brackets of the tank came off easilyand the heater pads installed nicely inside the brackets. Part of working under the van meant lifting it a bit. This time I just drove the rear dual wheels onto some 2x10 pieces (cut with 45° angles) instead of using the Ford supplied jack. I did jack the front as that's much more accessible. The SeeLevel system was interesting - it did not come with any installation instructions! Just three sensor strips, a panel, and a wiring harness to go into the panel all inside a plastic bag. After a search online I did find a PDF of the manual. It is a programmable system - you cut out parts of the circuit strips for programming - a very interesting design. Thus far I have the grey tank heater pad and pipe heater pad and the SeeLevel sensor installed and wired.

0 Comments

Leave a Reply. |

Details

AuthorCalvin here - after spending almost 33 years in education as a high school teacher, elementary teacher, and elementary administrator, it was time to retire! I did so happily and with no regrets; it was a terrific and fulfilling career. I do enjoy building projects as the design and building process is very therapeutic and you see a completed functional product in the end. Now to combine the build with another of Angela's and my passions - travel - is something we're really looking forward to. Archives

September 2022

Categories |

RSS Feed

RSS Feed