|

Vans are small spaces and control panels cast a LOT of light! Those little LED lights on switches, control panels, and microwaves will light up the entire interior of the van. Not so great for sleeping. On top of all that is the fact that the Maxxair fan lids are almost transparent so sunlight in the morning comes right through. I was covering up the light on the Victron Multiplus control panel with my jacket sleeve from the coat hook to the pull for the blind - hardly convenient (especially when you're half asleep and the sleeve falls away.)

0 Comments

Big windows are very nice to have... however they do take up wall space! The challenge with that is when sitting in the dining room, there's nothing to lean back against like in a regular chair/seat. Another problem was when the blinds were down and people would lean back; the slider handle (quite sharp edges) would get pressed into the blinds. It would take no time at all for a cut in the blind to form. After pondering what to do about these issues, I figured a seat rail in the window opening would be a good solution. Sure we would sacrifice a bit of the view but there would still be plenty of window to look out of. A piece of stair bull nose was perfect for the job.

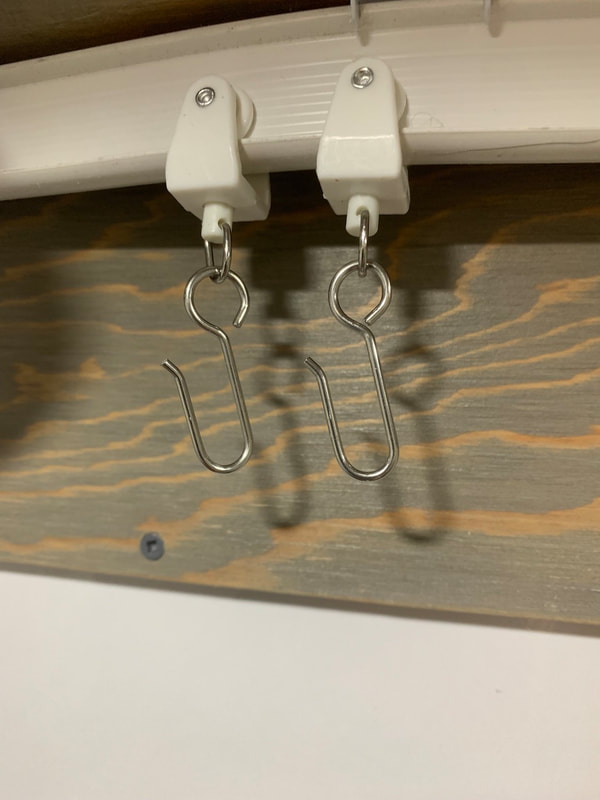

After our trip to Banff and Lake Louise (which involved hotel stays along with campsites) I figured that something had to be done to improve the closet function. Through the trip there was plenty of gear in there but it was just in a big pile! Not the easiest thing to access certain items. We also realized that we need much less hanging space than we thought. So one of those Ikea shoe hanging organizers and a separating shelf we needed.

The entry at the cargo door is very high off the ground. This posed a problem for entering and exiting comfortably. We had looked at electric retractable steps and permanent nerf bar types of steps and none really caught our fancy. There was one I kind of liked - it had a flat step that retracted or extended when you kicked it. But it was quite expensive and I was sure we would need some modifications to it for mounting. This is due to our grey water tank being in that location. In the end we're very happy with the folding metal step we bought online. It's very stable, has adjustable height, and folds and stores easily.

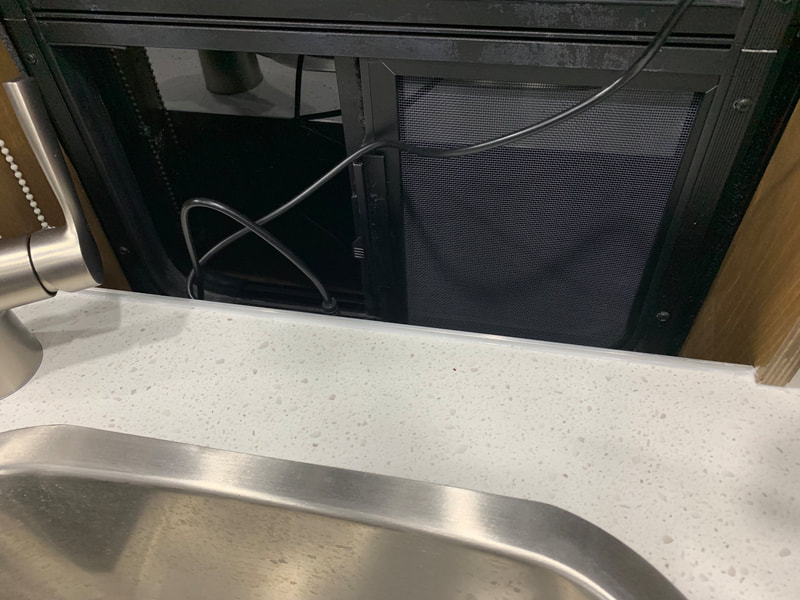

Countertop space was also a challenge on our test run. To help with that I did two things. 1) I put some rubber stops on the underside of the sink cutout/cover. That way it can sit side ways and expose about 1/3 opening of the sink while providing extra counter space near the outlet at the end of the counter. I also added an aluminum edge strip at the window opening to keep things from falling off the back of the counter into the window well. Lastly, I installed a flip up counter extension at the end of the counter at the cargo door opening. Our camping at Galiano Island was much more comfortable with all of the improvements:) We were trying to see if an "all electric" house was possible... In in the end, we decided it wasn't. On a website that I was frequenting, people were saying that the amount of battery we had (even though it is a large bank at 618 amp-hours of lithium) wouldn't be enough to provide the heat needed unless we were really going to rough it and also run the engine to charge the batteries with the alternator. We went camping a couple of times in early March. If we had plug in shore power - no problem, the electric heater produced plenty of heat to keep us warm and comfortable. But we tried a night at a campground with no plug in and it was about -2°C that night... it was quite cold, not unbearable but it did drain the battery down to about 30%. While we don't plan on chasing snow (we don't ski or snowboard) we knew there could be times when we might be at higher altitude and experience freezing temperatures even in summer.

All along I figured this would be something we needed to make a decision on. Our choices were to install a couple more batteries (for which we had room) or have a gas (regular gas or diesel) heater installed. The cost of the two options was similar. While adding a couple of batteries would give us some heating capacity, we would still need to recharge the batteries in order to have heat for a few days. In the end we decided to have an Espar S2D2 diesel heater installed. We could have gone with a gas unit but that meant dropping the gas tank and plumbing into the tank. There were some issues with that. 1) The gas tank would have to be dropped - not so easy especially with our grey and black tanks and drain pipes under the van. 2) The Transit doesn't have huge range based on the fuel tank capacity and mileage so I was hesitant to put even more draw on the gas. 3) The gas heater unit was physically larger than the diesel (although it does have a higher heat output - but I didn't think it was necessary given the size of the van interior.) We also had a 10L fuel tank installed inside the cabinet under the sink (the heater cubby is just under that cabinet). This amount of fuel will provide heat for days. Packing one or two 5L gas cans of kerosene would provide as much heat as we wanted.) It's also easy to buy more diesel (many gas stations) but especially more kerosene (Home Depot, Walmart, Lowes, etc. all sell it.) More money (oh well!) and a more time to re-jig the cabinet... but we're warm and happy! It will make the van much more comfortable and trips enjoyable. Today the last of the flooring went in. We also "moved in" most of our kitchen equipment. There are a few details still to be completed but functionally, Redford is complete! I think with any RV (and boat) ownership there will always be maintenance to be carried out, repair work (some minor... some major), and ongoing improvements being carried out so it's always a work in progress. It has been a challenging but fun project and we are so looking forward to testing it out and going on some trips. Now if only the weather and pandemic would cooperate! In reality we weren't planning on true winter camping in any event. So now we have time to test Redford, make final adjustments, and also clean up the work area.

From ordering to completion it has been just about a year. We ordered our Transit cargo van back in December of 2020. During the time that it took for it to arrive on May 1, 2021, we had purchased a great deal of our supplies and components. There were a few "misses" in some pieces that didn't work out but not a lot. My original timeline was the end of October - I'm a couple of months overdue but in reality there was almost one whole month of in-van work time lost due to the master control module failure, COVID vaccine recovery time, heat wave, and more than a few other "life got in the way" events (most of them happy ones though.) I'll make some modifications to the website in 2022 to highlight the main areas and features of Redford and then by spring we can start putting some entries into the travel section:) Today was a shopping day. Angela and I went out and spent most of the day shopping today. Part of the trip involved trying to find window coverings for the three Motion Windows and the read cargo door windows. I had brought home some "top down/bottom up" type of pleated blinds from a local big box retailer. The concept was great, pull the shade down and you get a privacy sheer, the pull the handle back up and you get a blackout privacy covering. The only problem was that when they were folded away to the top of the window casing, the profile was over 4" in height. In your home this might be okay because the top of the window is most likely higher up, i.e., above your head and not impeding your view. In a van the window is lower down and only 25" tall as well. That means more than 25% of the view out is blocked if you're standing.

After an early dinner (finished eating by 5:00 - we did skip lunch however...) I spent about 2.5 hours working in Redford. I made a knife holder for the top drawer and secured organizer blocks in the drawer. That way things shouldn't slide about too much when we're driving. I also prepped for installing the rest of the vinyl flooring tomorrow. That involved screwing down the floor boards and doing some vacuuming. As usual, in order to screw down the floor boards, I had to first lift them to see where the 2x4 supports ran underneath. In order to lift the boards, I has to take the cupboard doors off the fridge cabinet and also take the bottom drawer out of the kitchen cabinet. That meant emptying the drawer first, and so on. In the end, the boards are now countersunk, screwed in place, and vacuumed. Everything else has been put back in place as well so that tomorrow I can get right to flooring. It won't be as straight forward as in the dining area because the path is a bit narrower so I'll have to cut planks. Also there are a couple of corners to work around and more aluminum edge trim to install. 12/27/2021 Small finishing details - dish cabinets, assist handles, shower curtain, end tablesRead NowThere are lots of bits and pieces to finish off - and they all take time! It's been really cold and snowy around here; I have a 300W radiant heater that helps with my hands and body, but my feet freeze! Standing on the concrete floor sucks the heat out of my feet and it's been so cold, snowy, and windy that the snow actually blows in under the barn roof ridge cap, falls inside, and sticks to the cars, van, and floor inside the barn! I have to be careful because it makes the floor super slippery.

Merry Christmas - I hope everyone has a safe holiday and are able to connect with your family and friends to the degree that is comfortable and safe (FaceTime, phone, some in-person). The weather outside IS frightful... Besides COVID Omicron, we have heavy snow now and extreme cold (for this area anyways) coming this week. Working in the shop on the van is unpleasant - super cold on my hands. I discovered that if I take out our little 350W electric radiant heater, it makes things much more pleasant. I work right in front of the heater dish and things are good - it's just a pain having to move the plug and heater from place to place.

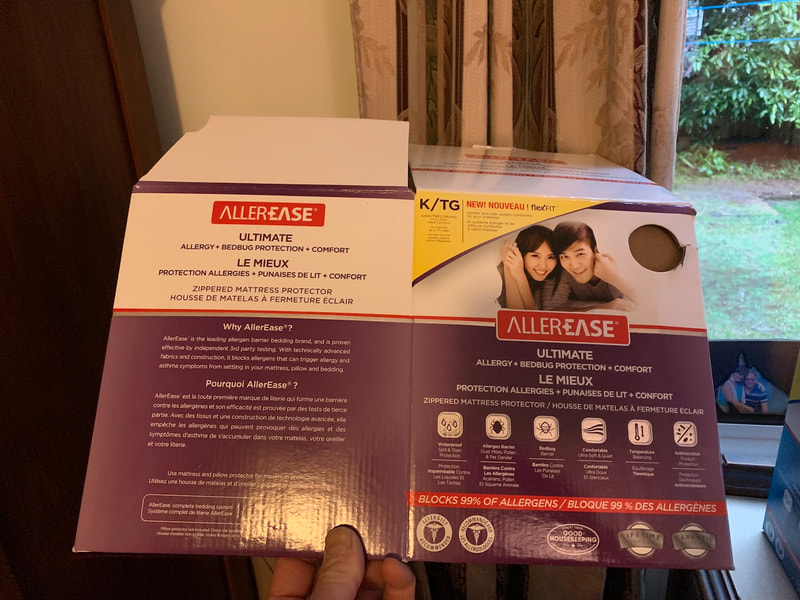

Very exciting this past week. We took our fabric, zippers, mattress covers, foam, and Redford over to our friends Evelina and Ray's place to make our cushion covers. Evelina is a terrific seamstress and while we helped a little bit with layout and a bit of cutting, she put in 99% of the work! They turned out great and the van looks nice inside with the cushions in place. The mattress covers were necessary as our mattresses are made from poly foam (3") and latex foam (2"). The latex foam is very soft and not very durable - lots of bits coming off when it rubs against other items. So to protect it we bought mattress covers from Walmart and Evelina modified them to zip over the foam prior to putting them in the finished covers. We almost had a fabric disaster. After Evelina had worked on the covers for 11 hours Ray let us know that we were really close to needing more fabric - they would let us know the next morning... I looked at the Ikea website (we were using drapes for most of the cover material) and saw on the website there was only ONE package remaining at each of the local stores. Yup - when they made the final cuts we needed one more panel of fabric. I went out to Ikea for opening and managed to grab the very last pack on the shelf. I think that fabric and drape is now discontinued so we were very fortunate! Now that we had extra fabric remaining from the new package, we had material to make a drape for behind the driving cabin and a cover for the large cargo door window. I had to study up on how to use the sewing machine! Everything has turned out quite well. I discovered that even though neodymium magnets are very strong, because the fabric is slippery against the van metal, you need lots of magnets to hold up the cargo door window panel (12 of them weren't enough!) Tomorrow we head over to our friends' place to have cushion covers made:) The timing is just right as I made good progress on the dining/sleeping area today. The Lagun table top was completed a couple of weeks ago and this week I made the extension top if there are more than just Angela and I eating. I had previously made some aluminum pieces for the key lock on the extension leg base but because the flooring vinyl we bought is so thick, those aluminum pieces wouldn't work. I ended up making a new one out of 3/16th steel which perfectly matches the vinyl plank we have.

|

Details

AuthorCalvin here - after spending almost 33 years in education as a high school teacher, elementary teacher, and elementary administrator, it was time to retire! I did so happily and with no regrets; it was a terrific and fulfilling career. I do enjoy building projects as the design and building process is very therapeutic and you see a completed functional product in the end. Now to combine the build with another of Angela's and my passions - travel - is something we're really looking forward to. Archives

September 2022

Categories |

RSS Feed

RSS Feed